Implants

Implants

Loupes

Regeneration

Drills and screws

Surgery

Periodontology

Endodontics

Thommen Medical is an independent family business. The success of our customers is always our top priority. Since the beginning, we have been committed to a single goal: to produce the best possible dental implant system – which is all we do.

We consistently rely on Swiss precision in manufacturing, rigorous quality control and collaboration with the best dental experts in the world. The result is a unique dental implant system that combines Swiss quality, simplicity and an innovative design, based on over 35 years of clinical experience.

We will continue to focus on the high demands of our customers for safety and aesthetics. We do everything to achieve this goal and stand by it with our name. We are Thommen Medical.

Driven by science, not trends, the Thommen Implant System is based on a unique, proven design, optimized over more than three decades of clinical success for the life of your patient

We focus on a portfolio of proven solutions that ensure safety and reliability for you and your patients. Working with Thommen Medical is remarkably different and we place great emphasis on personal service.

Every patient should have access to the best solution available. To be close to the leading experts and pulse of time, we work closely with an advisory board of renowned dental clinicians from around the world such as Ueli Grunder, Markus Hürzeler, Otto Zuhr, Kony Meyenberg, David Nisand, Mauro Merli and many others. Our products are tailored to their treatment concepts.

Whatever we do, perfection is our guiding principle. At Thommen Medical, we develop and produce all of our products in our own facility in Grenchen, Switzerland. By keeping all production and manufacturing processes in-house we are able to ensure that the highest of standards are met and maintained.

The safety of our products (for use on patients) is our top priority. Therefore, we guarantee our customers the highest product quality by using modern manufacturing and measuring technology. Our qualified employees, partners and suppliers ensure that all processes are continuously further developed in compliance with regulatory requirements. In this way, we guarantee Swiss precision for the highest demands from product development to sales.

The safety of our products (for use on patients) is our top priority. Therefore, we guarantee our customers the highest product quality by using modern manufacturing and measuring technology. Our qualified employees, partners and suppliers ensure that all processes are continuously further developed in compliance with regulatory requirements.

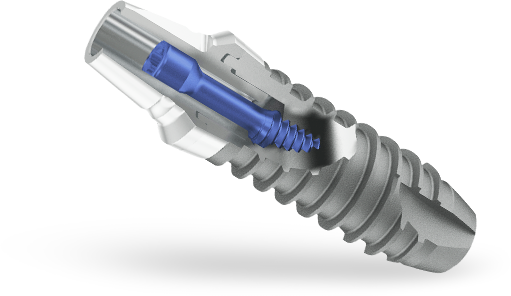

The parallel-walled universal implant.

The conical-cylindrical implant for extraction sockets and specific anatomical situations.

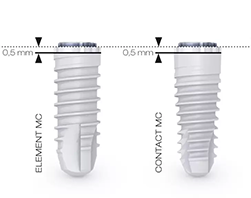

Individual soft tissue management.

A thin gingiva or limited vertical space for the prosthetic restoration often require a crestal implant position. Excellent results can be achieved with MC implants even in the esthetically demanding anterior region.

The distance between the implant position and bone helps to respect the biological structures. With RC implants, naturally esthetic results are easily achieved.

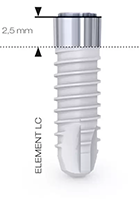

In the edentulous jaw an uneven gingival height often requires a longer neck height. LC implants are ideally suited for transgingival use in hybrid prosthetics.